I started spinning Harlequin by Inglenook Fibers (Merino, camel, alpaca and silk) in December of 2023. For this project, I picked five non-Spanish Peacock spindles.

Yes, I own—and even use—spindles from other makers! Left to right, this photo shows Shop Rat, Woodland Handcrafts, The Spindle Shop, Bristlecone, and Stephen Willette/Aaron Slater.

It took about a month and a half to finish spinning (mid-February), and then…

…well, you know. Plycrastination!

The singles had been “resting” for a whopping five months when I added this project to my Tour de Fleece plans.

My biggest plying block here—like several of the spins mentioned in my initial 2024 Tour de Fleece post—was complete lack of forethought. I had no plan. I hadn’t even looked at the braid before I started taking off chunks of it to spin. Now I had no vision for how the colors might look with different plying options. I finally decided to chain ply the singles, so the colors would be preserved in the same progression as in the dyed fiber…whatever that may have been! Chain plying used to be a nightmare for me, but plying balls have made it a more realistic option.

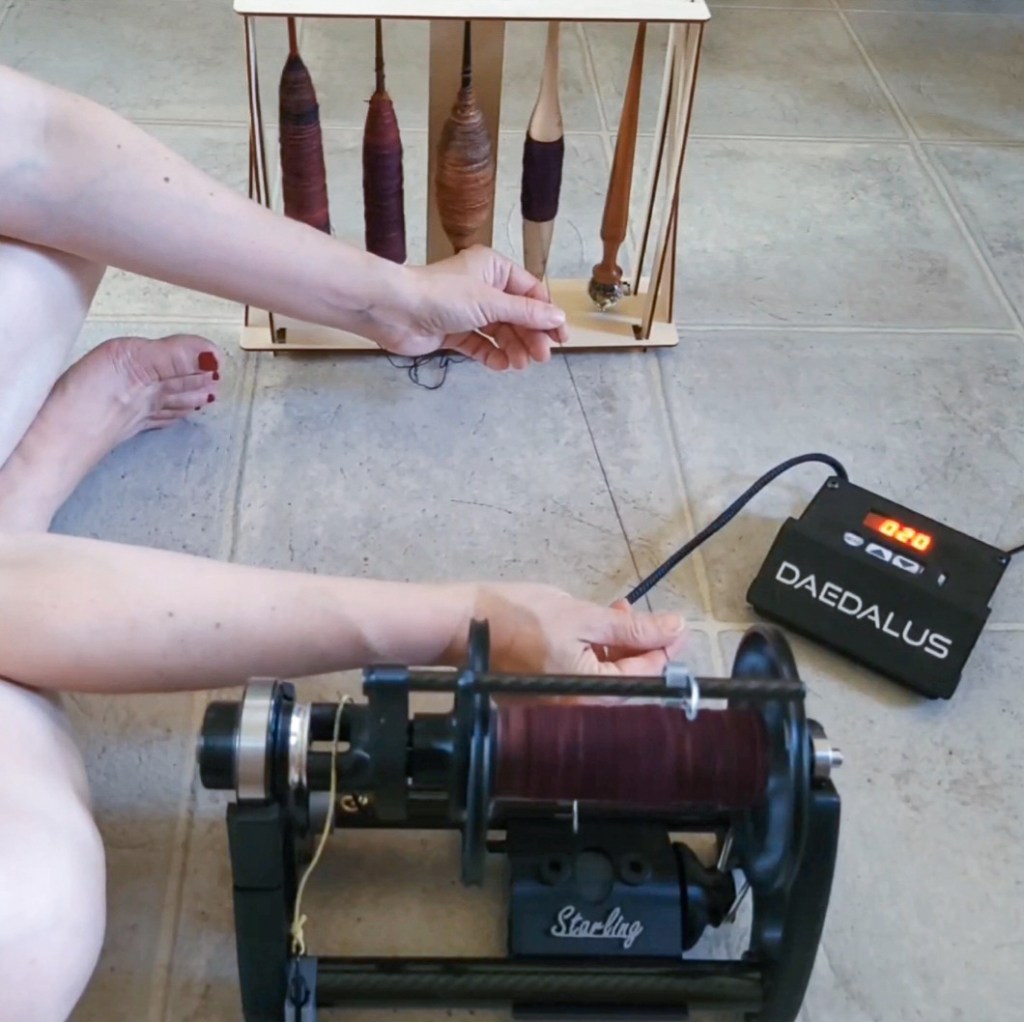

Unfortunately, many of the spindles didn’t fit in my plying stand. There are many other options to get the singles off the spindles, but debating the best technique helped postpone the inevitable plying by a few more days. I finally decided to wind the singles onto a Starling bobbin, using my storage stand to hold the spindles.

(Sorry for the terrible picture quality. I forgot to take an actual photo, so this is a screenshot from an Instagram reel. If you have Instagram, here’s the full reel.)

Reeling also provides an extra opportunity for twist to even out, although that would work better if the singles had farther to travel between spindle and bobbin. But I was very worried about the spindles getting yanked out of the stand, so I opted for a compact setup this time.

I’d still rather use my plying stand wherever possible, because the spindles turn more freely with their weight distributed between two points, rather than just one. Several times I thought the singles might break as the Starling tugged on the yarn and the spindle only reluctantly moved. Luckily, the singles held and now I have a backup option for spindles that won’t fit in the plying stand.

Note: to pull this off, I needed to switch the Starling from being drive belt-driven (Scotch tension) to bobbin-driven (Irish tension). I don’t really know what this means, as wheel mechanics, even on an eSpinner, are a mystery to me. Luckily, I found great instructions on how to do it on YouTube.

Once the yarn was on the bobbin, I wrapped a chain plying ball…

…then added twist to the chained singles using the Starling (back in Scotch tension mode).

Five months of plycrastination isn’t bad compared to other projects. Clearly “failure to plan” is one of my recurring blocks when it comes to finishing yarn, but it’s not the only one. Stay tuned for further plying adventures in future posts.

Summary:

Harlequin by Inglenook Fibers on Merino, camel, alpaca and silk

- Started spinning 12/29/2023 on supported spindles

- Finished spinning 2/14/2024

- Finished plying 7/4/2024 using my Daedalus Starling

- 370 yards, chain-plied at 16 WPI

- Spindles freed: five

If you haven’t already read them, here are links to my other posts for Tour de Fleece 2024:

Beautiful! I’m working my way to try a plying ball for cable ply. Thanks for your encouragement.

LikeLike

I think 5 months is a great improvement from the ones during TDF! Well done! I dug out my wool dryer balls I bought to make ornaments to make ply balls. Just have to figure out under which bag of fiber they are hiding lol.

LikeLike

[…] degree of plycrastination, especially compared to the previous Tour de Fleece WIPs which either had zero plan, or for which I had neglected to write down my […]

LikeLike

[…] Harlequin […]

LikeLike

[…] Harlequin […]

LikeLike

[…] Harlequin […]

LikeLike

[…] Harlequin […]

LikeLike